Selecting Cable Pulling Accessories for Power Cables

2025-12-12

Selecting the correct Cable Pulling Accessories is a crucial step in any electrical project. By considering cable type, environment, and installation requirements, installers can protect Electrical Wires & Cables and improve workflow efficiency. Combining high-quality accessories with durable metal racks or trays from Jinhua Bode Hardware Technology Co., Ltd. creates a safer, more organized, and long-lasting cable infrastructure.

1. Understanding Cable Types and Requirements

Before choosing any accessory, it is crucial to know the type of cable you are handling. Power cables can vary widely:

Single-core vs. multi-core cables: Multi-core cables require careful handling to prevent twisting or internal damage.

Armored vs. non-armored cables: Armored cables may need stronger grips or specialized pulling socks.

Flexible vs. rigid cables: Flexibility affects how accessories such as rollers or pulleys should be used.

Knowing the cable specifications helps you select compatible Cable Pulling Accessories and avoid potential installation errors.

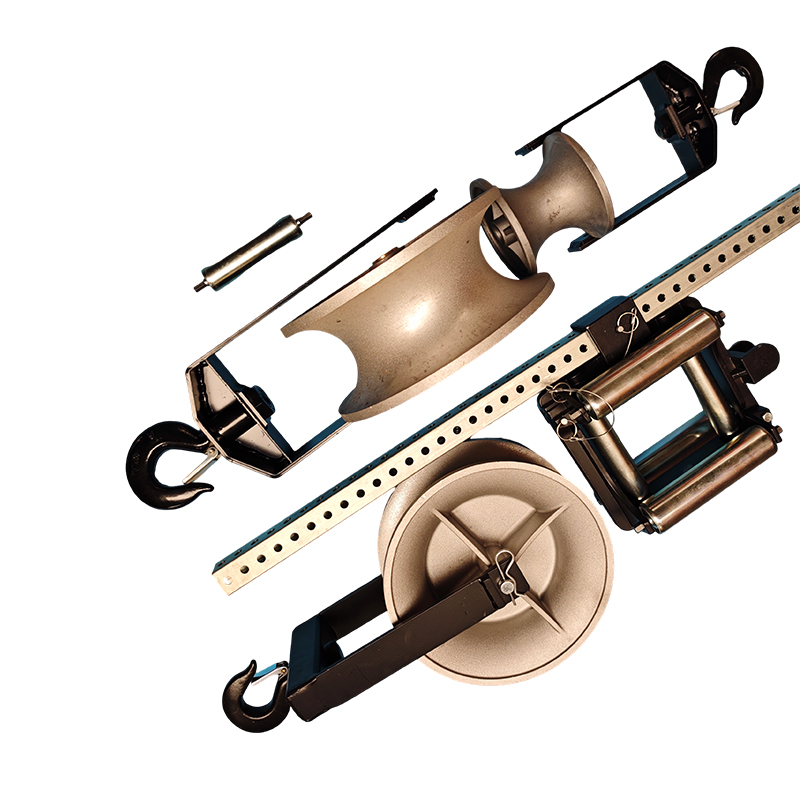

2. Common Cable Pulling Accessories and Their Uses

Different accessories are designed for specific purposes. Some commonly used options include:

Cable grips and pulling socks: Attach securely to the cable end for controlled pulling.

Rollers and pulley systems: Reduce friction when running cables through conduits or around corners.

Lubricants and guides: Facilitate smooth movement for long cable runs and prevent insulation damage.

Spacers and rollers in trays: Ensure multiple cables do not rub against each other.

Choosing the Correct combination of these accessories is key to a safe and efficient installation process.

3. Factors to Consider When Selecting Accessories

Several factors should guide your selection of Cable Pulling Accessories:

Cable diameter and weight: Heavier or thicker cables require stronger grips and support.

Installation environment: Outdoor, industrial, or confined spaces may require specialized accessories.

Length of cable run: Longer distances benefit from rollers and intermediate supports to reduce tension.

Conduit configuration: Sharp bends or vertical runs may require pulleys or flexible guides.

By evaluating these factors, installers can minimize stress on Electrical Wires & Cables and reduce the risk of damage.

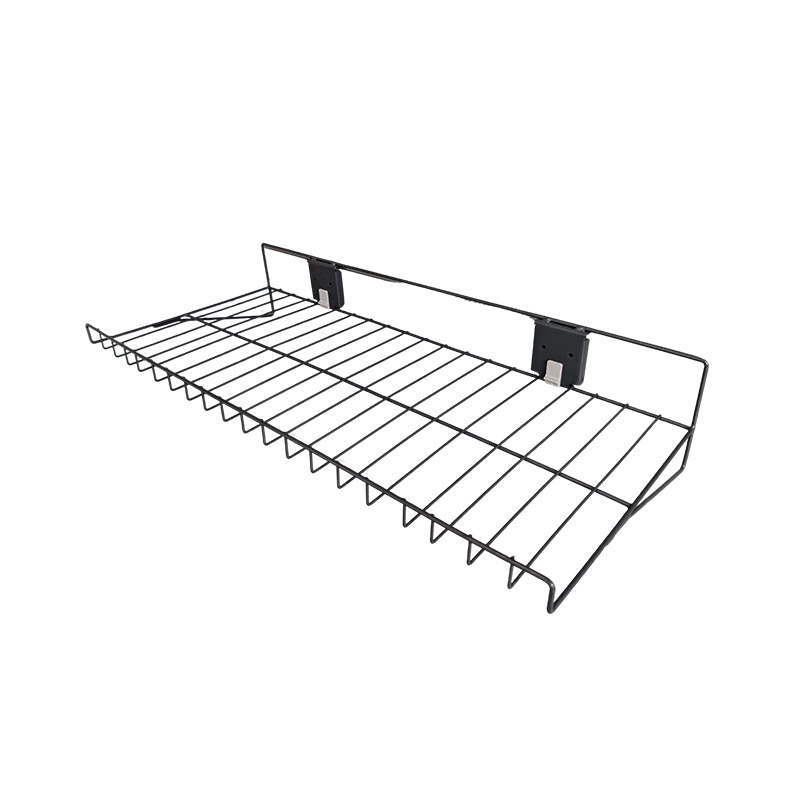

4. Integration with Cable Management Solutions

Using Cable Pulling Accessories alone is not enough. Integrating them with proper cable management systems enhances safety and organization:

Install metal racks or cable trays to support cables during and after installation.

Use clamps and ties to secure cables in long horizontal runs.

Organize cables by type, voltage, or function to simplify maintenance and troubleshooting.

Jinhua Bode Hardware Technology Co., Ltd. provides durable metal shelving and racks that work seamlessly with pulling accessories, creating an organized workspace and reducing clutter.

5. nicely Practices During Installation

Even with the Correct accessories, following proper procedures is essential:

Inspect all accessories before use for wear or damage.

Plan the cable path to avoid unnecessary bends or obstructions.

Apply controlled pulling force to prevent overstressing the cable.

Monitor cable tension constantly, especially during long runs.

Maintain team communication for coordinated pulling operations.

These practices help ensure Electrical Wires & Cables are installed efficiently and safely.

6. Maintenance and Long-Term Considerations

After installation, evaluate how the accessories and cable management system will impact long-term maintenance:

Keep cable trays and supports free of debris.

Inspect clamps, rollers, and accessories periodically for wear.

Ensure proper labeling and documentation for future modifications.

Proper integration of Cable Pulling Accessories with organized cable storage extends cable life and reduces repair needs.

English

English

English

English 中文简体

中文简体 Español

Español