Avoiding Damage During Electrical Wires & Cables Install

2025-12-19

Avoiding damage during cable installation is a combination of planning, proper accessory use, and careful technique. By selecting the Correct Cable Pulling Accessories, applying controlled pulling methods, and supporting cables correctly, installers can protect Electrical Wires & Cables and ensure reliable, long-lasting performance. Integrating cable management solutions from Jinhua Bode Hardware Technology Co., Ltd. further enhances organization, safety, and durability of any electrical installation.

1. Identify Potential Damage Risks

Before starting the installation, it is essential to identify potential hazards that could damage Electrical Wires & Cables:

Sharp edges or corners in conduits or trays.

Excessive pulling tension during installation.

Abrasion against rough surfaces along the cable path.

Twisting or bending cables beyond recommended radii.

Recognizing these risks in advance allows installers to take preventive measures, ensuring a smooth and safe installation.

2. Use Proper Cable Pulling Accessories

The selection and correct use of Cable Pulling Accessories play a major role in protecting cables. Key accessories include:

Cable grips and socks: Securely hold cables without compressing them.

Pulling ropes and swivel hooks: Facilitate controlled movement and reduce twisting.

Rollers and pulleys: Minimize friction, especially around bends.

Lubricants: Reduce stress on the cable jacket in long or complex runs.

Using high-quality accessories helps distribute the pulling force evenly and prevents accidental damage.

3. Implement Controlled Pulling Techniques

Even with the Correct accessories, poor technique can still harm cables. Consider these nicely practices:

Pull cables at a steady, moderate speed. Avoid sudden jerks or stops.

Measure pulling tension using tension meters to stay within cable specifications.

Maintain team coordination when handling long or heavy cables to prevent kinks or tangles.

Avoid pulling multiple cables simultaneously in a way that may cause abrasion between them.

By combining proper accessories with controlled pulling techniques, installers protect the integrity of Electrical Wires & Cables.

4. Protect Cables in Conduits and Trays

Even after pulling, cables need proper support to prevent future damage:

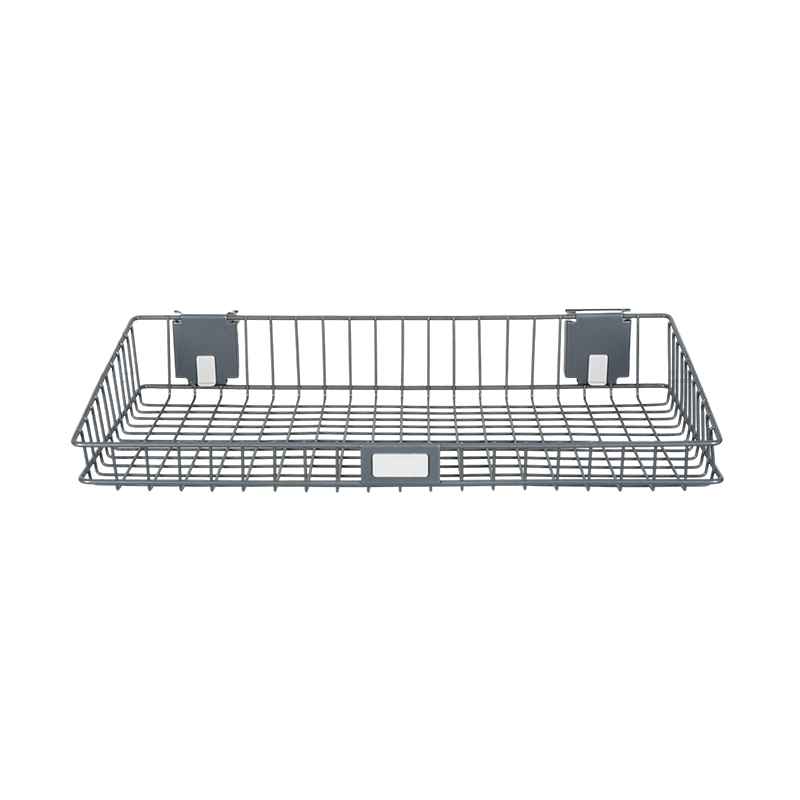

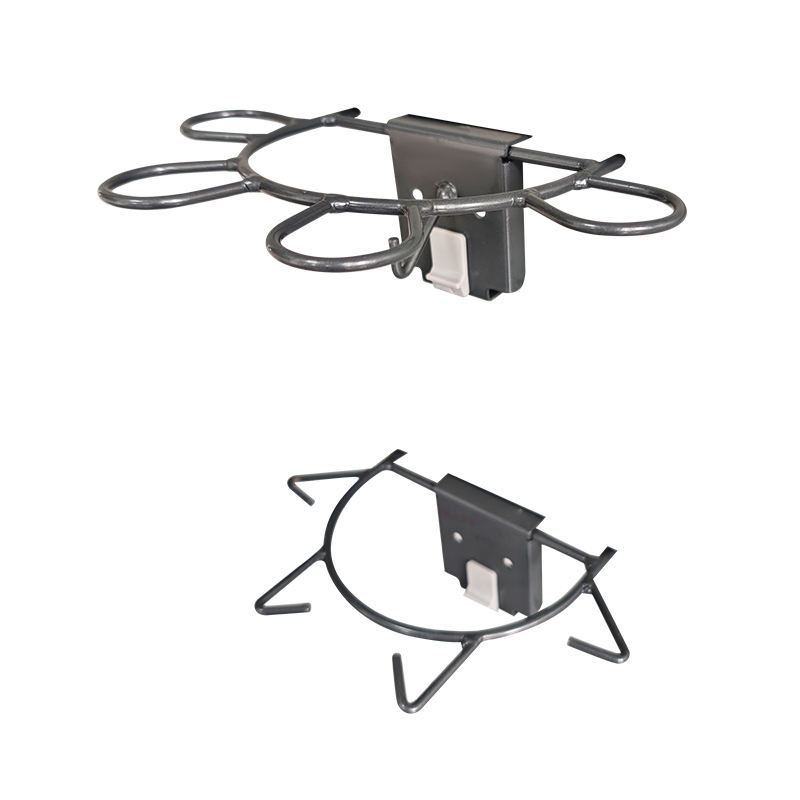

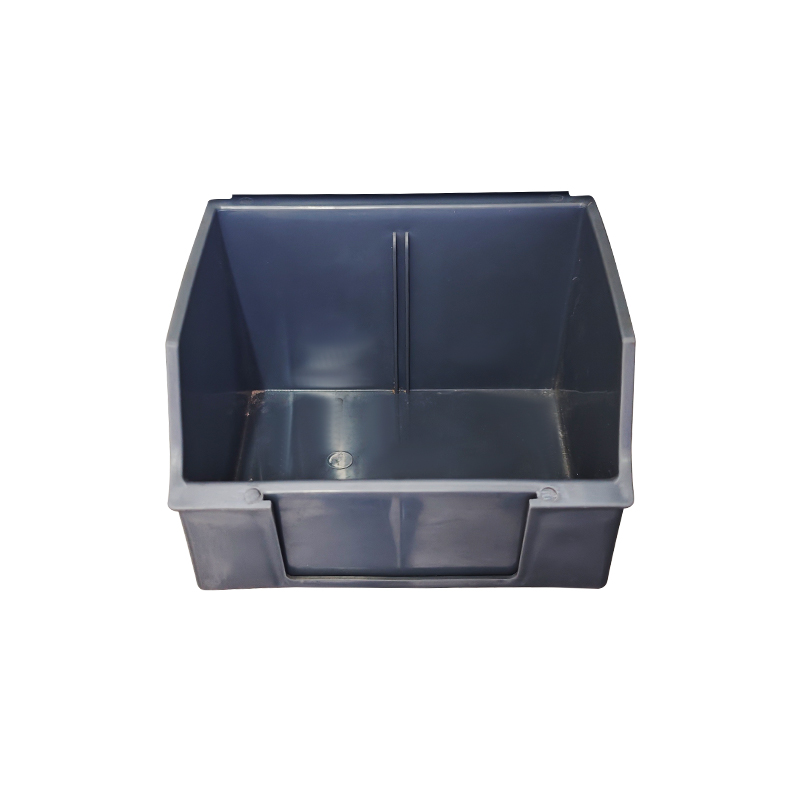

Install cable trays or metal racks to provide structural support along long runs.

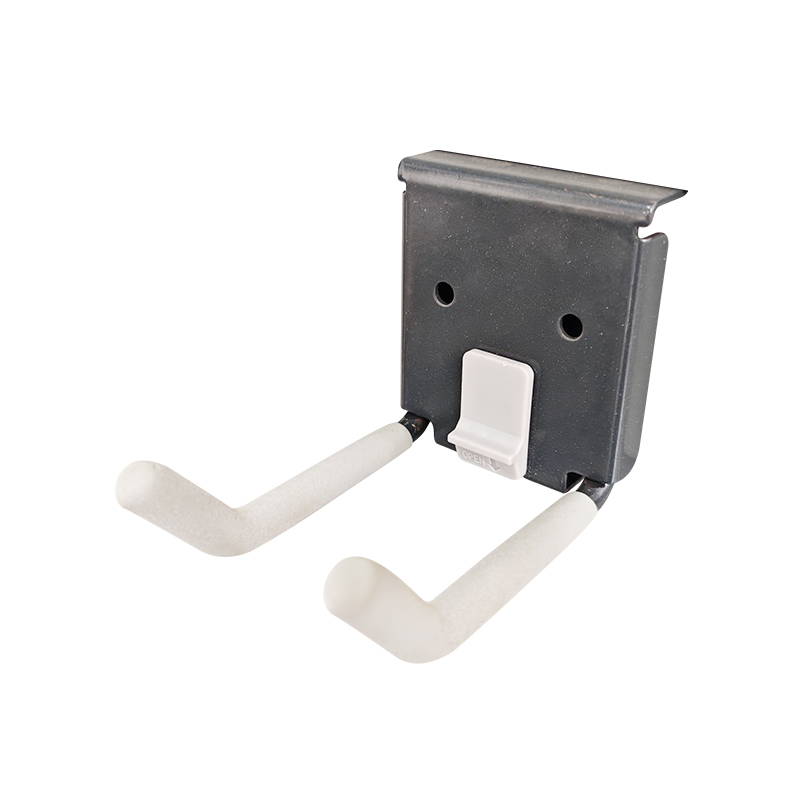

Use spacers and clamps to prevent cables from rubbing against each other or against sharp edges.

Maintain proper spacing between cables to avoid heat buildup in bundled installations.

Jinhua Bode Hardware Technology Co., Ltd. offers a variety of sturdy metal racks that help keep cables organized and secure, reducing strain and potential damage over time.

5. Inspect and Maintain Installed Cables

After installation, regular inspection and maintenance help ensure long-term reliability:

Check for any signs of abrasion, cuts, or insulation damage.

Tighten loose clamps and reposition cables if necessary.

Document cable runs for easy troubleshooting in the future.

Replace any worn or damaged pulling accessories before the next project.

Routine inspection is a proactive approach to maintaining cable integrity and preventing unexpected failures.

Installing Electrical Wires & Cables safely is critical to the longevity and reliability of any electrical system. One of the more important steps in installation is preventing damage to cables during pulling and routing. Using the correct Cable Pulling Accessories can significantly reduce the risk of cuts, abrasions, and overstressing the wires. Jinhua Bode Hardware Technology Co., Ltd. provides durable racks and cable organization solutions that work hand-in-hand with pulling accessories to safeguard cables during installation.

English

English

English

English 中文简体

中文简体 Español

Español