Installing storage systems like Wall Hanging Garage Shelves and Wall Mounted Garage Hooks can make a huge difference in garage organization, but one issue many homeowners encounter...

READ MOREWire Mesh Sleeves And Accessories Maker

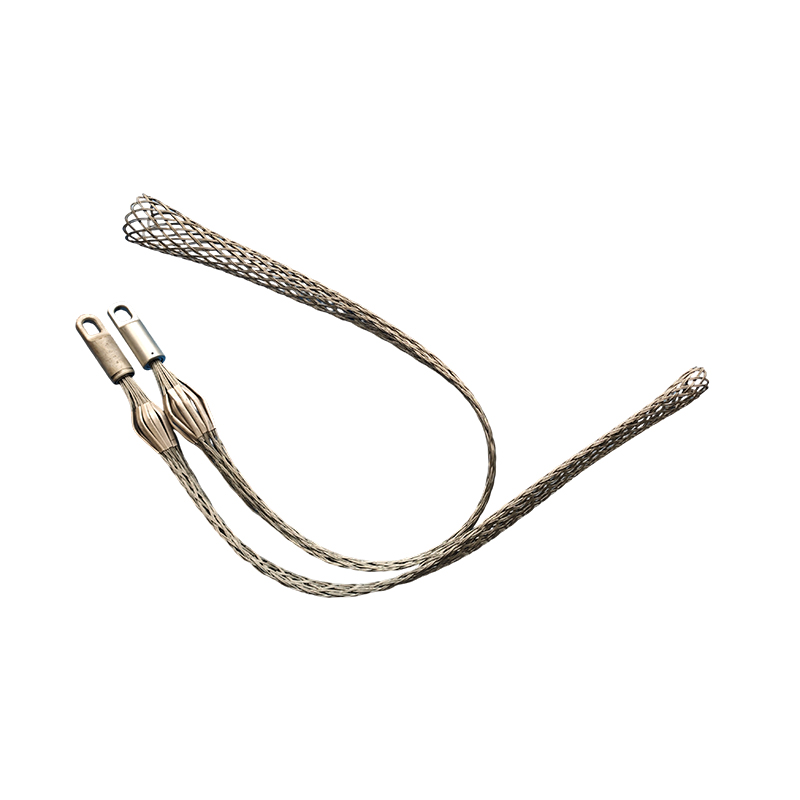

Cable mesh sleeves are made from high-quality materials such as steel ropes or nylon. They combine strength and flexibility, making them ideal for applications where cables need protection from abrasion, cuts, or environmental hazards. The mesh design ensures a reliable attachment to the cables while maintaining flexibility to allow for bending around corners or passing through narrow spaces. Cable mesh sleeves are available in various sizes, specifications, and designs to meet the specific requirements of different cable installation or construction conditions.

T-type mesh sleeve: Replaces one-time-use cable clamps and can be reused for cable pulling.

K-type mesh sleeve: Adds a rotating lifting ring to facilitate cable pulling and rotation.

M-type mesh sleeve: Designed for cables that need to support greater pulling force, featuring a multi-layer woven structure to enhance the sleeve’s ability to wrap the cable.

K-type mesh sleeve: Offers convenient mid-force transfer for cables, with a sewn structure after the mesh is wrapped around the cable.

G-type mesh sleeve: Balances the force distribution with a dual lifting ring structure.

RA-type mesh sleeve: Features a dual mesh structure for easy cable-to-cable connection.

RB-type mesh sleeve: Prevents disconnection at the cable-to-cable junction by using a full mesh structure.

Some mesh sleeves also include connectors or teeth to provide a more secure attachment to fixed equipment or cables.

These mesh sleeves ensure reliable protection and support for cables under various operating conditions.

Bode is not only a manufacturer, but also your trusted warehousing optimization partner. We are customer-oriented, continuously innovative, and committed to providing smarter, more durable and more environmentally friendly shelf products to help global companies improve warehousing efficiency, reduce operating costs, and move towards a cleaner and more sustainable future together!

-

-

Garage organization often starts with installing Wall Hanging Garage Shelves and Wall Mounted Garage Hooks to keep tools and equipment off the floor and easily accessible. But once...

READ MORE -

A garage often relies on smart storage solutions such as Wall Hanging Garage Shelves and Wall Mounted Garage Hooks to maximize usable space and keep tools or gear within reach. Sti...

READ MORE -

Organizing a garage becomes a priority for many homeowners, and Wall Hanging Garage Shelves combined with Wall Mounted Garage Hooks often represent a smart way to free up floor spa...

READ MORE -

A well‑organized garage doesn’t just look neat — it enhances efficiency and safety. When planning your Wall Garage Storage, one of the top concerns among DIYers and homeowners is h...

READ MORE -

Installing Heavy Duty Garage Storage Hooks properly is a key step in building an effective Wall Garage Storage area. For many homeowners and DIYers, the promise of a clutter‑free g...

READ MORE -

Have you ever installed Wall Garage Storage panels only to find that parts of your system simply aren’t working as you expected? Whether you’re hanging bicycles, power tools, or se...

READ MORE -

When you invest time and effort into organizing your garage, nothing is more frustrating than finding your Heavy Duty Garage Storage Hooks failing to hold the weight you expected —...

READ MORE -

Adhering to nicely practices for cable installation and using appropriate Cable Pulling Accessories ensures the integrity of Electrical Wires & Cables, reduces installation ris...

READ MORE -

Installing heavy cables requires careful planning, the Correct accessories, and proper techniques. Using cable grips, pulling socks, rollers, and metal support systems ensures that...

READ MORE -

Avoiding damage during cable installation is a combination of planning, proper accessory use, and careful technique. By selecting the Correct Cable Pulling Accessories, applying co...

READ MORE -

Selecting the correct Cable Pulling Accessories is a crucial step in any electrical project. By considering cable type, environment, and installation requirements, installers can p...

READ MORE

Cable Mesh Sleeves and Equipment Industry Knowledge Extension

Cable Mesh Sleeves and Equipment

Cable mesh sleeves and equipment provide an efficient and flexible way to manage and protect cables in various environments. These sleeves are designed to bundle multiple wires together, reducing clutter and preventing tangling while maintaining accessibility for adjustments or maintenance. The open-weave structure allows for reliable airflow, which helps prevent heat buildup around electrical cables, contributing to safer operation. Ideal for industrial settings, home entertainment systems, or computer setups, cable mesh sleeves can adapt to different diameters and cable types, providing a versatile solution for both temporary and long-term installations. Alongside the sleeves, compatible equipment such as connectors, end caps, and mounting accessories ensures that installations remain secure and organized. The lightweight and durable material used in these products resists abrasion and environmental wear, allowing them to endure regular handling without losing shape or protective qualities. Users can easily cut the sleeves to length or combine multiple sleeves to cover larger cable assemblies, making them suitable for complex setups in offices, workshops, or server rooms. By grouping wires neatly, cable mesh sleeves reduce the risk of accidental disconnections and simplify troubleshooting, ultimately saving time during maintenance. Whether for electrical, networking, or audiovisual applications, these sleeves provide a practical balance of protection, flexibility, and neat organization.

Wire Mesh Sleeves and Accessories

Wire mesh sleeves and accessories are designed to deliver reliable cable management while offering durability and adaptability in diverse applications. These sleeves encase wires and cables, protecting them from friction, abrasion, and environmental exposure, which is especially valuable in industrial, automotive, or electronic installations. The flexible mesh structure accommodates varying cable thicknesses and shapes, making it straightforward to customize the setup according to specific requirements. Accessories such as end caps, clamps, and fasteners complement the sleeves, ensuring a secure fit and preventing loose or shifting wires. Wire mesh sleeves maintain airflow around the cables, which helps prevent overheating and supports consistent performance for electrical systems. Their construction is lightweight yet robust, allowing them to withstand repeated handling and installation stresses without compromising the protection they provide. Cutting and adjusting sleeves to size is simple, providing an adaptable solution for both new installations and retrofits. By organizing cables into a single, structured bundle, wire mesh sleeves reduce tangling and improve overall workspace safety, especially in crowded or high-traffic areas. They are suitable for applications ranging from industrial machinery wiring to home network or entertainment system management, combining functional protection with a clean, professional appearance. Overall, these sleeves and accessories create a reliable and organized cable environment while requiring less maintenance effort.

Braided Cable Sleeves and Tools

Braided cable sleeves and tools offer a flexible approach to organizing and safeguarding wiring in residential, commercial, and industrial contexts. The braided design allows the sleeve to expand and contract, accommodating multiple cable sizes while ensuring a snug fit. This elasticity makes installation straightforward, even in tight spaces or complex wiring arrangements. Braided sleeves protect cables from abrasion, dust, and environmental factors, helping maintain the integrity of electrical systems over time. Tools designed to work with these sleeves, including cutting devices, insertion aids, and end caps, support precise and efficient installations. The sleeve material is lightweight yet durable, capable of handling repeated handling without fraying or losing its shape. Braided sleeves also facilitate better airflow around cables, which reduces heat accumulation and supports consistent electrical performance. They are particularly useful for organizing clusters of wires, making maintenance, upgrades, and troubleshooting easier by keeping cables clearly separated and accessible. These sleeves can be applied in computer systems, audiovisual setups, automotive wiring, and industrial machinery, providing a neat and protective solution. By combining practical functionality with a clean visual arrangement, braided cable sleeves and their associated tools help maintain order, reduce wear on wires, and improve overall safety in various environments.

English

English

English

English 中文简体

中文简体 Español

Español