Installing storage systems like Wall Hanging Garage Shelves and Wall Mounted Garage Hooks can make a huge difference in garage organization, but one issue many homeowners encounter...

READ MOREWholesale Electrical Equipment

Electrical tools play a crucial role in the power industry, ensuring the efficient and safe completion of infrastructure construction and cable laying operations. This product category includes a range of essential tools designed to assist professionals in the installation, maintenance, and repair of electrical facilities. The main subcategories within this category include cable handling tools, cable pulling and laying tools, and electrical installation tools and equipment.

Cable handling tools are specifically designed to facilitate the smooth and orderly handling of cables. These tools are essential for tasks involving the storage, transportation, unspooling, and anti-winding of cables on construction sites, allowing electricians to manage cables more efficiently. Proper use of cable reels and other equipment ensures rational transportation, smooth unwinding, prevention of tangling, and proper storage of cables on site, thereby preventing damage to the cables during construction, improving operational efficiency, and reducing potential hazards.

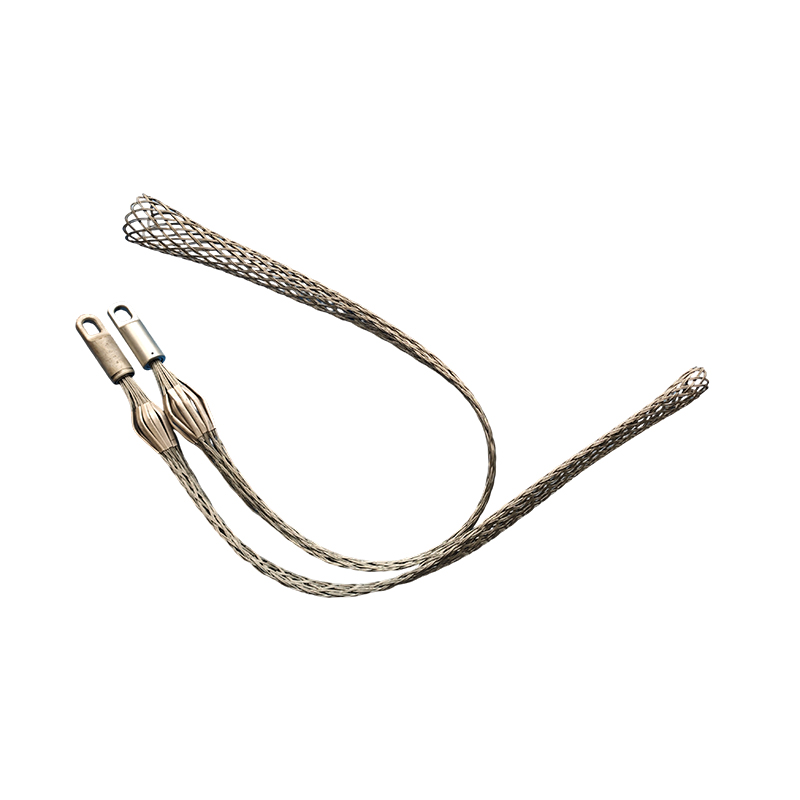

Cable pulling and laying tools are designed to provide additional support for the proper laying and positioning of cables during construction. These tools include cable pulling machines, cable feeding machines, and other cable traction devices, as well as accessories such as wire guides, cable clamps, and cable sleeves. They are used to safely guide cables through conduits, walls, or ceilings, reducing the risk of physical damage and accidents. These tools help standardize and control the cable laying process while simplifying the installation workflow by providing a more controlled construction environment.

Electrical installation tools, such as wire strippers, tensioners, wire cutters, and clamps, along with electric tools for on-site construction like pipe benders and heat guns, are designed to improve the safety and efficiency of electrical work. Each tool is intended to ensure that electricians can complete their tasks effectively while adhering to safety standards.

Together, these tools provide a comprehensive solution for electrical facility construction, enabling professionals to perform their work with precision, safety, and efficiency. The right electrical tools are essential for the professional execution of electrical facility construction tasks.

Bode is not only a manufacturer, but also your trusted warehousing optimization partner. We are customer-oriented, continuously innovative, and committed to providing smarter, more durable and more environmentally friendly shelf products to help global companies improve warehousing efficiency, reduce operating costs, and move towards a cleaner and more sustainable future together!

-

-

Garage organization often starts with installing Wall Hanging Garage Shelves and Wall Mounted Garage Hooks to keep tools and equipment off the floor and easily accessible. But once...

READ MORE -

A garage often relies on smart storage solutions such as Wall Hanging Garage Shelves and Wall Mounted Garage Hooks to maximize usable space and keep tools or gear within reach. Sti...

READ MORE -

Organizing a garage becomes a priority for many homeowners, and Wall Hanging Garage Shelves combined with Wall Mounted Garage Hooks often represent a smart way to free up floor spa...

READ MORE -

A well‑organized garage doesn’t just look neat — it enhances efficiency and safety. When planning your Wall Garage Storage, one of the top concerns among DIYers and homeowners is h...

READ MORE -

Installing Heavy Duty Garage Storage Hooks properly is a key step in building an effective Wall Garage Storage area. For many homeowners and DIYers, the promise of a clutter‑free g...

READ MORE -

Have you ever installed Wall Garage Storage panels only to find that parts of your system simply aren’t working as you expected? Whether you’re hanging bicycles, power tools, or se...

READ MORE -

When you invest time and effort into organizing your garage, nothing is more frustrating than finding your Heavy Duty Garage Storage Hooks failing to hold the weight you expected —...

READ MORE -

Adhering to nicely practices for cable installation and using appropriate Cable Pulling Accessories ensures the integrity of Electrical Wires & Cables, reduces installation ris...

READ MORE -

Installing heavy cables requires careful planning, the Correct accessories, and proper techniques. Using cable grips, pulling socks, rollers, and metal support systems ensures that...

READ MORE -

Avoiding damage during cable installation is a combination of planning, proper accessory use, and careful technique. By selecting the Correct Cable Pulling Accessories, applying co...

READ MORE -

Selecting the correct Cable Pulling Accessories is a crucial step in any electrical project. By considering cable type, environment, and installation requirements, installers can p...

READ MORE

Electrical Tools Industry Knowledge Extension

Electrical Tools: Reliable Instruments for Everyday Use

Electrical tools are essential instruments for professionals and hobbyists working with wiring, circuits, and electrical installations. Designed to support both precision and efficiency, these tools cover a wide range of applications, from basic repairs to complex assembly tasks. Users can find hand tools like pliers, wire strippers, and screwdrivers, as well as power-assisted options such as drills, testers, and multifunctional tools for electrical maintenance. Safety and convenience are considered in the design of these tools, with ergonomic handles, insulated materials, and intuitive layouts to reduce the risk of accidents while providing ease of use. Whether for residential, commercial, or industrial projects, electrical tools allow users to handle wiring, connection, and installation tasks with confidence. By combining durability and consistent performance, they ensure reliable operation in various conditions. Routine maintenance and thoughtful selection of the right tool for the job can extend its service life, while modular designs make it easy to adapt tools to specific tasks. With the continuous evolution of electrical systems, modern tools also incorporate features that cater to new standards, helping users stay efficient without compromising safety. Electrical tools remain a practical choice for anyone seeking a dependable solution for hands-on electrical work.

Electrical Equipment: Functional Solutions for Power Management

Electrical equipment plays a crucial role in managing, distributing, and controlling electrical energy across different settings. These products include items like transformers, circuit breakers, switches, and distribution panels, all designed to maintain consistent power flow while ensuring operational safety. They are widely used in residential buildings, commercial facilities, and industrial plants to protect devices, prevent overloads, and support the efficient use of energy. Quality materials and robust construction help equipment withstand daily wear and environmental factors, including heat, moisture, and dust. Ease of installation and maintenance is a key focus, allowing users to quickly integrate equipment into existing systems and monitor performance without complications. Electrical equipment is often paired with safety features, such as grounding, overload protection, and surge control, which collectively contribute to safer environments for both personnel and devices. With proper selection and use, electrical equipment enables reliable operation for a wide range of applications, from lighting and HVAC systems to production machinery and data centers. Its combination of functionality, adaptability, and durability makes it a practical investment for anyone managing electrical infrastructure.

Electrical Devices: Everyday Tools for Smart Connectivity

Electrical devices are designed to make daily life more convenient, efficient, and connected. These products include appliances, meters, smart sensors, and other consumer or industrial electronics that rely on electricity to function. They are widely applied in homes, offices, and industrial settings, serving purposes such as measurement, automation, communication, and energy management. Devices are created with usability in mind, offering intuitive interfaces, responsive controls, and compatibility with various systems. Safety considerations are built into the design, including insulation, overload protection, and compliance with regulatory standards. Regular maintenance and thoughtful usage ensure consistent operation over time, while modular and upgradeable designs allow adaptation to evolving needs. Electrical devices not only support practical tasks but also contribute to improved efficiency and convenience in everyday activities. From powering small appliances to monitoring energy consumption or controlling lighting, these devices combine utility with reliability. Their flexible application makes them suitable for a wide range of scenarios, whether for personal use or professional environments. By providing consistent performance, electrical devices remain an integral part of modern life, supporting both routine and specialized tasks.

English

English

English

English 中文简体

中文简体 Español

Español